Perforated metal straps are common in construction, plumbing and HVAC work. They secure pipes, ducts, conduits and many other components. Because they are flexible and easy to adjust, these straps fit a wide range of applications.

Most straps are made from stainless steel or galvanized steel. Both materials offer strength, durability and corrosion resistance. This makes them suitable for homes, commercial buildings and industrial installations.

The holes along the strap allow flexibility without reducing strength. These perforations also make cutting, shaping and fastening simple. As a result, the straps work well even in complex or tight spaces.

Perforated metal straps are also cost-effective. They help reduce vibration, minimize noise in ducting systems and allow quick inspection or maintenance. Understanding how they work will help you achieve safer and more efficient installations.

____________________________________________________________________________________________________

What Are Perforated Metal Straps?

Perforated metal straps are thin metal strips with evenly spaced holes. These holes provide flexibility and make installation easier. The straps are used to hold, support or stabilise pipes, ducts, cables and other components.

They work with different types of fasteners such as screws and bolts. This makes them useful in many situations that require reliable support.

Key characteristics include:

- Strong and durable construction

- Flexible design due to perforations

- Compatible with many types of fasteners

- Easy to cut and adjust on-site

Straps come in different widths and thicknesses to match various load requirements. They help maintain a neat and organized installation, supporting safety standards and building code requirements.

____________________________________________________________________________________________________

Common Materials

Perforated straps are usually made from:

Stainless Steel

- Excellent corrosion resistance

- Suitable for humid, coastal or outdoor environments

- Ideal for long-term installations

Galvanized Steel

- More affordable

- Zinc coating protects against rust

- Works well for general-purpose installations

Choosing the right material ensures your system remains strong, safe and efficient.

____________________________________________________________________________________________________

Key Features and Benefits

Perforated metal straps provide several advantages:

✔ Adjustable and Versatile

Pre-punched holes allow installation around different shapes and sizes.

✔ Corrosion Resistant

Both stainless steel and galvanized steel offer long-lasting protection.

✔ Lightweight but Strong

High strength-to-weight ratio supports heavy components without adding unnecessary load.

✔ Noise & Vibration Control

Helps stabilise piping and duct systems for quieter operation.

Summary of Benefits

- Easy installation

- Flexible applications

- Long service life

- Works with many fastening systems

____________________________________________________________________________________________________

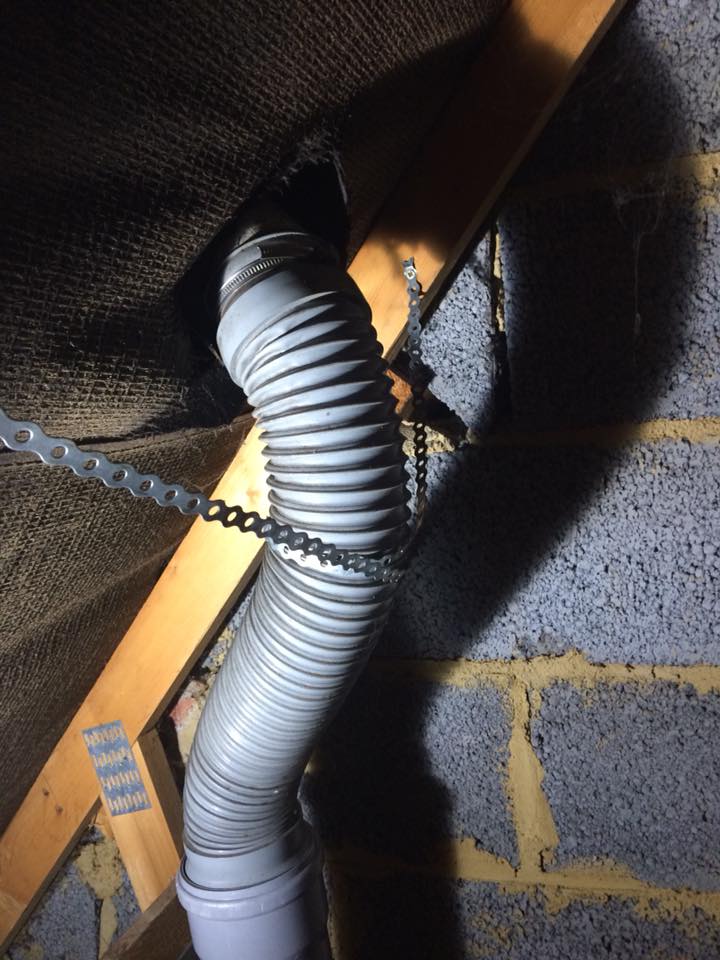

Applications in Plumbing and HVAC

Perforated straps are widely used in:

Plumbing

- Supporting water, waste and drainage pipes

- Holding pipes in the correct alignment

- Reducing vibration and securing joints

HVAC Systems

- Suspending ducts and vents

- Supporting insulation or flexible ducting

- Maintaining airflow and system stability

General Use

- Cable trays

- Light fixtures

- Signage support

- DIY and small-scale construction work

____________________________________________________________________________________________________

Installation Tips

A proper installation improves safety and performance. Follow these steps:

1. Choose the Right Strap

Select the correct width, thickness and material for your load and environment.

2. Measure and Cut

Cut the strap to the required length using tin snips or appropriate tools.

3. Use Suitable Fasteners

Ensure screws or bolts match your application and surface.

4. Align and Secure

Keep the strap straight and evenly tensioned across the load.

5. Check Regularly

Inspect for loose fasteners or signs of wear over time.

Proper installation ensures the system remains stable and requires less maintenance.

____________________________________________________________________________________________________

Choosing the Right Strap Guide

Before selecting a perforated strap, consider:

Environment

- Moist or dry

- Indoor or outdoor

Load Requirement

- Lightweight piping

- Heavy ducting or structural loads

Material Compatibility

- Stainless steel for harsh environments

- Galvanized steel for general use

Fastener Compatibility

Ensure holes match the type of fasteners you plan to use.

Evaluating these factors helps you choose the most reliable option for your project.

____________________________________________________________________________________________________

Maintenance, Safety and Compliance

Regular checks help keep systems safe and problem-free.

Maintenance Tips

- Look for rust or corrosion

- Check for loose or missing fasteners

- Replace worn or damaged straps

- Ensure alignment and tension remain correct

Compliance

Always follow local building codes when installing support straps. This ensures safety and helps prevent system failures.

____________________________________________________________________________________________________

Conclusion

Perforated metal straps are essential in plumbing, HVAC and general construction. They are durable, flexible, cost-effective and easy to install. Choosing the right material and following proper installation practices ensures long-term performance and safety.