Perforated strapping is a versatile fastening solution used across construction, HVAC, plumbing, and electrical installations. Choosing the right strapping requires understanding three critical factors: size, gauge thickness, and load-bearing strength. This guide walks you through the selection process to ensure your project has the proper support and compliance.

What Is Perforated Strapping?

Perforated strapping, also called perforated metal strap or hanger strap, is a flat metal band with evenly spaced holes along its length. These perforations allow for flexible attachment points using screws, bolts, or nails. The strapping secures pipes, conduit, ductwork, and structural elements to walls, ceilings, or framing members.

Key Selection Factors

1. Size and Width

Perforated strapping comes in standard widths ranging from 3/4 inch to 2 inches, with 1-inch and 1-1/4-inch being the most common for general applications.

How to choose width:

- 3/4-inch strapping: Light-duty applications like securing small conduit or lightweight piping (under 1-inch diameter)

- 1-inch strapping: Standard residential and commercial use for pipes up to 2 inches in diameter

- 1-1/4-inch and wider: Heavy-duty industrial applications, larger diameter pipes (3+ inches), or situations requiring extra surface contact

The width should provide adequate contact with both the item being secured and the mounting surface. A general rule: the strapping width should be at least half the diameter of the pipe or conduit being supported.

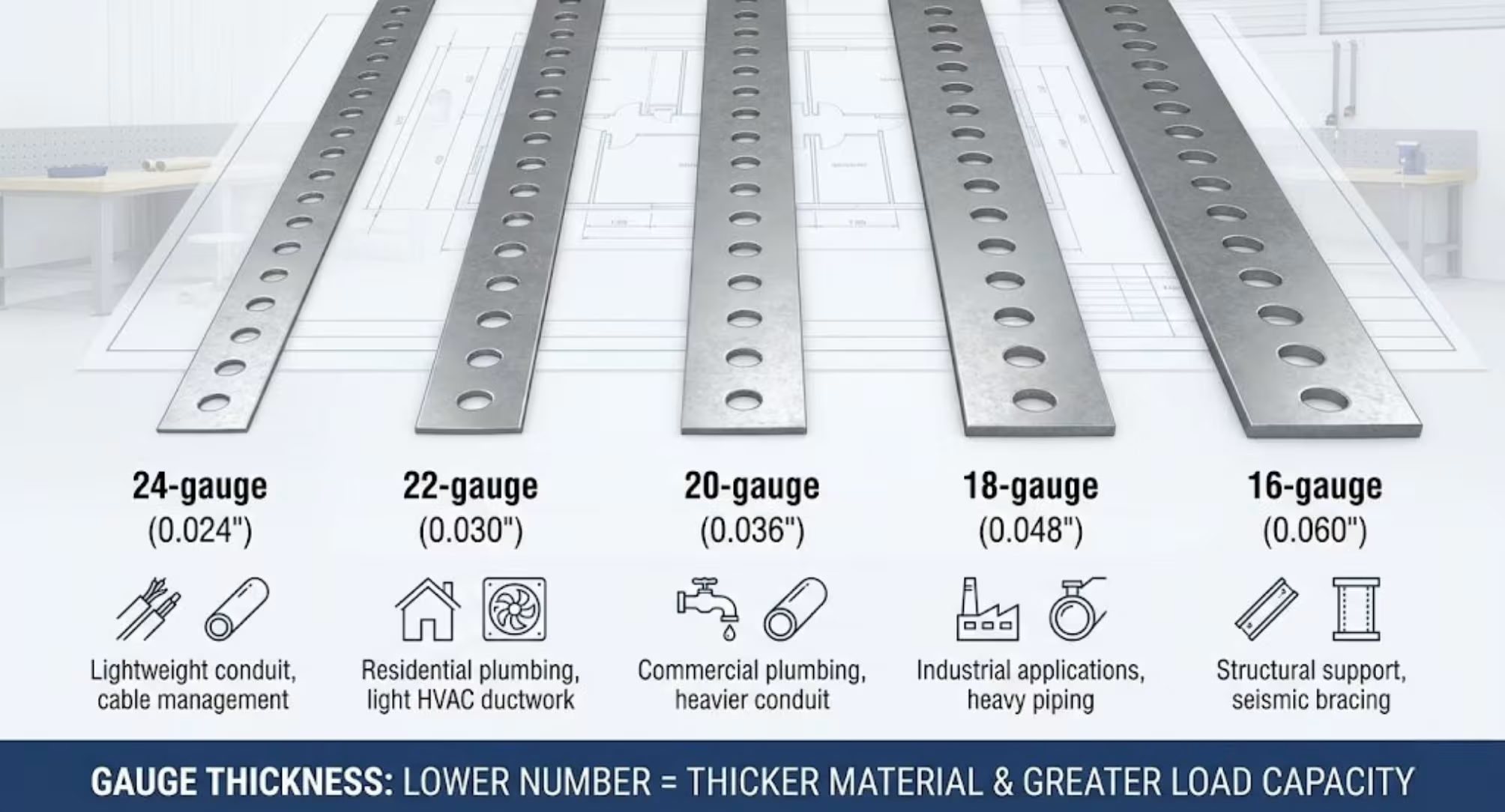

2. Gauge Thickness

Gauge refers to the metal thickness, with lower numbers indicating thicker, stronger material. Common gauges for perforated strapping range from 24-gauge (thinnest) to 12-gauge (thickest).

Standard gauge applications:

- 24-gauge (0.024 inches): Lightweight electrical conduit, cable management

- 22-gauge (0.030 inches): Standard residential plumbing, light HVAC ductwork

- 20-gauge (0.036 inches): Commercial plumbing, heavier conduit runs

- 18-gauge (0.048 inches): Industrial applications, heavy piping systems

- 16-gauge and below: Structural support, seismic bracing, extreme load conditions

Thicker gauge strapping costs more but provides significantly greater load capacity and durability. Always check local building codes, as many jurisdictions specify minimum gauge requirements for specific applications.

3. Load-Bearing Strength

The strength of perforated strapping depends on both the gauge thickness and the material composition. Most strapping is manufactured from either galvanized steel or stainless steel.

Material strength considerations:

- Galvanized steel: Standard choice offering good corrosion resistance and strength for indoor and protected outdoor applications

- Stainless steel (304 or 316): Superior corrosion resistance for coastal, chemical, or high-moisture environments; higher tensile strength

Load capacity estimation: Working load limits vary by manufacturer, but general guidelines include:

- 22-gauge galvanized: approximately 200-300 lbs working load

- 20-gauge galvanized: approximately 400-500 lbs working load

- 18-gauge galvanized: approximately 600-800 lbs working load

Always consult manufacturer specifications for exact load ratings. Remember that working load is typically one-fifth to one-quarter of the breaking strength to provide an appropriate safety factor.

Application-Specific Selection Guide

HVAC Systems

For ductwork and air handling equipment, use 22-gauge minimum for residential systems and 20-gauge for commercial installations. Spacing between supports should not exceed 10 feet for horizontal runs.

Plumbing

Water-filled pipes are heavy. Use 20-gauge minimum for pipes up to 2 inches in diameter, and 18-gauge for larger pipes. Hot water systems may require additional consideration for thermal expansion.

Electrical Conduit

Follow National Electrical Code (NEC) requirements, which typically specify support intervals based on conduit type. EMT conduit can generally use 24-gauge strapping, while rigid conduit may require 22-gauge or heavier.

Seismic Bracing

Earthquake-prone regions require special consideration. Many jurisdictions mandate 16-gauge or heavier strapping with specific spacing intervals and attachment methods for critical utilities.

Installation Best Practices

- Spacing: Support points should be spaced according to code requirements, typically every 4-10 feet depending on the application and material being supported.

- Attachment: Use appropriate fasteners for your mounting surface. Concrete requires anchors, wood framing uses screws or nails, and steel framing needs self-drilling screws.

- Tensioning: Strapping should be snug but not overtightened. Over-tightening can deform pipes or create stress points that lead to failure.

- Protection: For copper or other soft materials, consider using protective padding between the strapping and the pipe to prevent abrasion or galvanic corrosion.

Common Mistakes to Avoid

- Under-sizing gauge: Using strapping that’s too thin for the load leads to sagging, failure, or code violations

- Improper spacing: Exceeding maximum support intervals causes excessive stress on mounting points

- Wrong material: Using standard galvanized strapping in corrosive environments accelerates deterioration

- Inadequate fasteners: The strapping is only as strong as its weakest point—cheap or improperly sized fasteners compromise the entire system

Frequently Asked Questions

1. What gauge perforated strapping do I need for 2-inch pipe?

For 2-inch pipe, use 20-gauge perforated strapping as a minimum. This gauge provides adequate strength for water-filled pipes and meets most building code requirements. For commercial or industrial applications with 2-inch pipe, consider 18-gauge for added safety margin and compliance with more stringent codes.

2. How far apart should perforated strapping supports be spaced?

Perforated strapping support spacing depends on the application. For horizontal plumbing runs, space supports every 6-8 feet maximum. HVAC ductwork requires supports every 10 feet. Electrical conduit spacing varies by type: EMT conduit needs support every 10 feet, while rigid conduit can span up to 12 feet. Always verify spacing requirements with local building codes, as requirements vary by jurisdiction.

3. What is the difference between 22-gauge and 20-gauge strapping?

The difference between 22-gauge and 20-gauge strapping is thickness and load capacity. 22-gauge strapping measures 0.030 inches thick with a working load of approximately 200-300 pounds, suitable for residential plumbing and light HVAC. 20-gauge strapping measures 0.036 inches thick with a working load of 400-500 pounds, making it appropriate for commercial applications and heavier pipe systems. The thicker 20-gauge costs slightly more but provides significantly better performance.

4. Can I use galvanized strapping outdoors?

Yes, you can use galvanized perforated strapping outdoors, but with limitations. Standard galvanized strapping works well in protected outdoor locations with minimal moisture exposure. For coastal areas, high-humidity environments, or direct weather exposure, use stainless steel strapping (304 or 316 grade) instead. Stainless steel resists corrosion far better than galvanized steel in harsh outdoor conditions and prevents rust staining on building surfaces.

5. What size strapping do I need for 1-inch conduit?

For 1-inch conduit, use 3/4-inch or 1-inch wide perforated strapping at 24-gauge minimum for EMT (thin-wall) conduit, or 22-gauge for rigid conduit. The 1-inch width provides better surface contact and stability than narrower strapping. Support spacing should not exceed 10 feet for EMT conduit runs. If the conduit run contains multiple bends or supports heavy cable fills, increase to 22-gauge strapping for added strength.

Conclusion

Selecting the right perforated strapping involves balancing size, gauge, and strength requirements with your specific application needs and budget. When in doubt, err on the side of heavier gauge material—the marginal cost difference is insignificant compared to the consequences of system failure or code violations.

For critical applications or when working with unfamiliar materials, consult with a structural engineer or qualified professional to ensure your strapping selection meets all safety and performance requirements.

Need Help Choosing the Right Strapping?

Our team of technical experts is ready to help you select the perfect perforated strapping for your specific application. Whether you’re working on a residential project or large-scale commercial installation, we can provide product recommendations, load calculations, and code compliance guidance.

Contact us today for personalized assistance with your strapping selection, bulk pricing, or technical specifications.