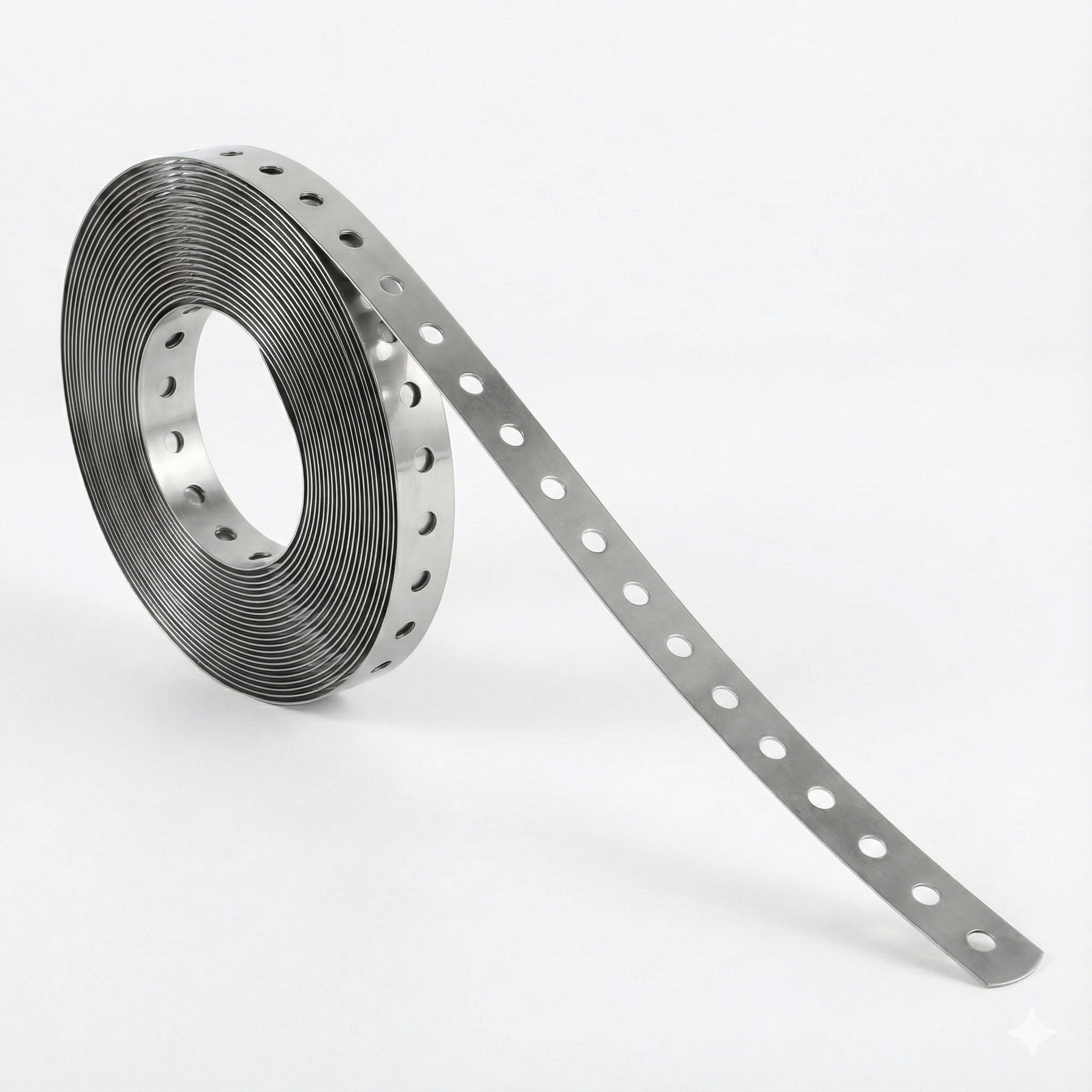

Metal plumbers tape, metal strapping with holes, metal tape with holes—different names, same idea. It is a flexible metal strip with evenly spaced holes that makes it incredibly easy to fix, hang, support, or secure all kinds of pipes, ducts, cables, and structures. For many contractors, this is the quiet hero in the toolbox: cheap, strong, and ready for almost any on-site problem.

What Exactly Is Metal Plumbers Tape?

Metal plumbers tape (sometimes called hanger iron, perforated metal strapping, or punched metal tape) is a roll of thin steel with holes punched along its entire length. The material is usually galvanized steel for corrosion resistance, though stainless steel and copper versions are also used in more demanding environments.

Those small, regular holes are what make metal tape with holes so practical. They let you cut the length you need, wrap or loop it around an object, and fix it in place using screws, nails, or bolts—without any special tools beyond basic hand tools on site.

Typical Uses of Metal Strapping With Holes

Professionals in plumbing, HVAC, electrical, and construction use perforated metal tape in a wide range of situations.

1. Hanging and Supporting Pipes

One of the most common uses is supporting pipes under ceilings, along walls, or inside service shafts. The metal tape wraps around the pipe and anchors back to the structure, with the holes allowing precise adjustment of height and position.

2. HVAC Duct and Flexible Duct Support

In HVAC work, metal strapping with holes is widely used to hang round ducts, rectangular ducts, and insulated flexible ducts. Installers like it because the strap is flexible enough to follow the shape of the duct but strong enough to carry the load when properly sized and anchored.

3. Electrical Conduit and Cable Management

Electricians use metal tape with holes to support conduits and cable bundles where they need a quick, adjustable fixing solution. It can be screwed to beams or walls, then looped around the conduit, making it useful in both temporary and permanent installations.

4. Light Framing, Bracing, and Repairs

On job sites, perforated metal tape often becomes a “problem solver” for:

- Bracing light frames

- Securing small equipment

- Reinforcing fixings

- Quick repairs where a custom bracket is not available

Because it comes in rolls, workers can cut exactly what they need and avoid waiting for custom hardware.

Materials, Finishes, and Corrosion Resistance

Most metal plumbers tape is made from mild steel, which gives a good balance of strength, formability, and cost. To prevent rust, manufacturers typically add:

- Galvanized coating for general indoor and light outdoor use

- Painted or coated finishes for improved corrosion resistance or identification

- Stainless steel for harsh or marine environments

Galvanized metal plumbers tape is the default choice in many plumbing and HVAC jobs because it resists corrosion in damp spaces like basements and plant rooms.

Choosing the Right Metal Tape With Holes

Not all perforated strapping is the same. A few key factors help you choose the right product for each job.

1. Width and Thickness

Wider and thicker tape generally supports heavier loads. Lightweight options are fine for small pipes or cables, while heavier gauges are better for larger ducts or bundles.

2. Hole Size and Spacing

The holes must be compatible with the screws, nails, or bolts used on site. Standard punched metal tapes use round or oval holes spaced at regular intervals, making it easy to line up fixings without measuring every time.

3. Length and Packaging

Most products come in rolls, often from 10 m up to 30 m or more, which allows installers to cut exactly what they need while keeping waste low.

4. Environment and Corrosion Risk

For dry indoor areas, standard galvanized tape is usually sufficient. For outdoor, coastal, or highly humid environments, stainless steel or enhanced coatings may be worth the extra cost to avoid premature corrosion.

Installation Basics: How Metal Plumbers Tape Is Used On Site

Although every manufacturer has its own guidelines, the practical steps on site are usually similar.

Step 1: Plan the Support Points

Installers first decide where the strapping will connect to the structure and where it will wrap around the pipe, duct, or other component.

Step 2: Cut the Tape to Length

Using snips or a suitable cutting tool, they cut the required length from the roll, often allowing a bit of extra length to adjust and overlap if needed.

Step 3: Fix One End to the Structure

The first end of the metal tape with holes is attached to a beam, wall, or ceiling using compatible screws, nails, or anchors, passing through one of the perforations.

Step 4: Wrap and Secure the Load

The tape is then looped under or around the pipe or duct before returning to the structure, where it is fixed again through a convenient hole. The installer can pull the tape to achieve the right height and tension before driving the second fastener.

Step 5: Check Load and Safety

Finally, the installer checks that the tape is not over‑stressed, that all fixings are tight, and that there are no sharp edges exposed where they could cause injury or damage cables or insulation.

Safety and Good Practice

Because metal strapping with holes is made from thin steel, it can have sharp edges after cutting. Installers typically wear gloves and eye protection when handling or cutting the tape, especially when working overhead.

It is also important not to exceed the recommended load capacity for a given width and thickness of tape. For heavy loads or critical applications, solid steel hangers or engineered brackets may be more appropriate than light perforated strapping.